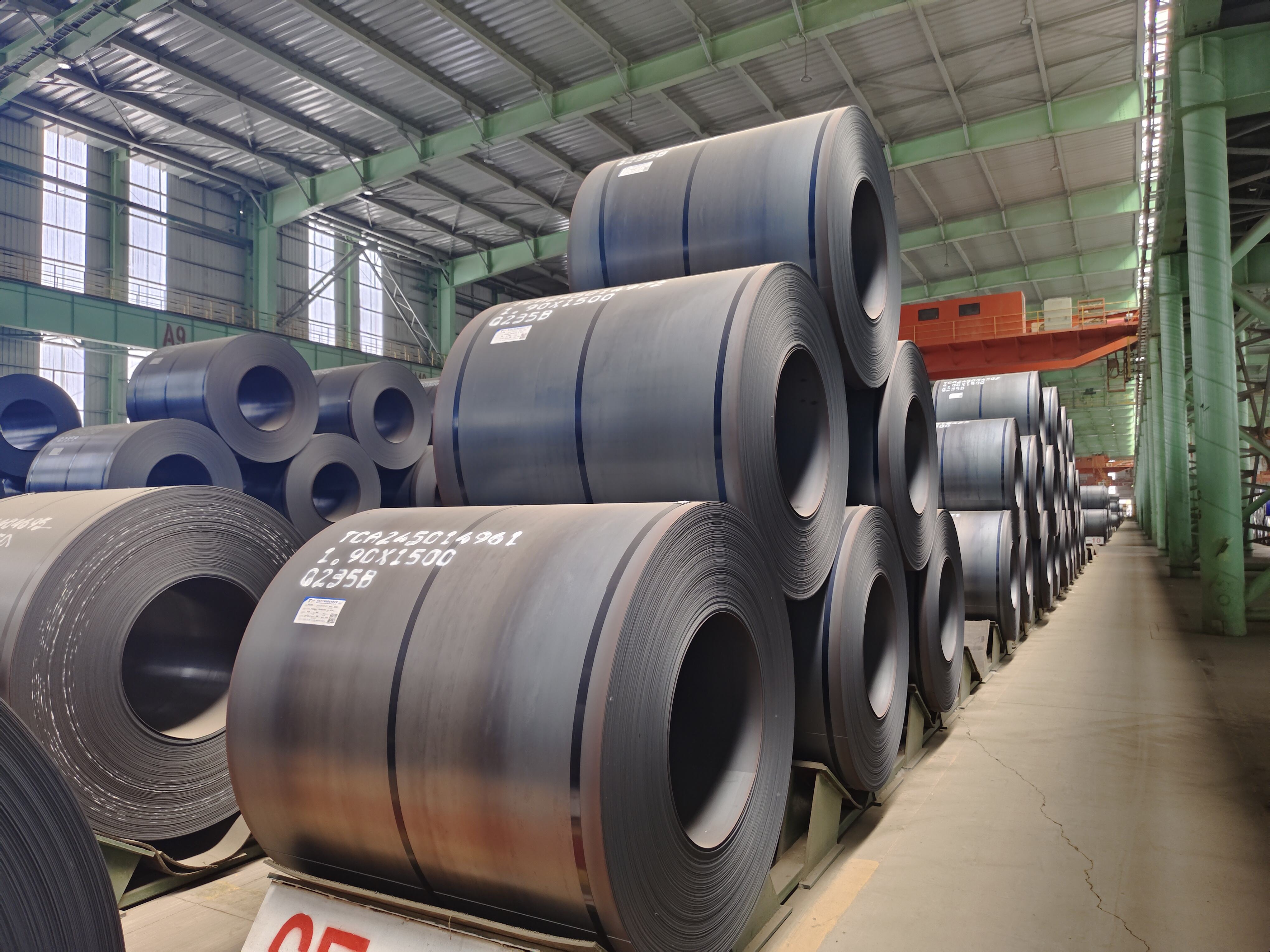

Low, medium and high carbon steel is made in the shape of coils and they have unique set of properties which makes them suitable for specific types of applications. They also have been categorized based on type of application, tensile strength and percentage of carbon content. For instance, up to 0.25% of carbon content is classified as low carbon, the range of 0.25% to 0.6% is medium and finally there is a high carbon steel which has more than 0.6% to 1% of carbon. Each of the sequences offer distinct characteristics that are interesting to further explore those who are specialized in a certain industry. Low carbon steel can mainly be used in structural applications and automotive parts because of its ability to be welded. TSEN with its range of 0.25 to 0.6% is ideal in machinery and equipment because it strikes a balance between tensile strength and toughness. The greatest percentage of carbon content is more beneficial in tools where heavy robust treatments are the only means of operation. Each of the grades as described above helps the organization in making the right selection for the projects that they are leading.