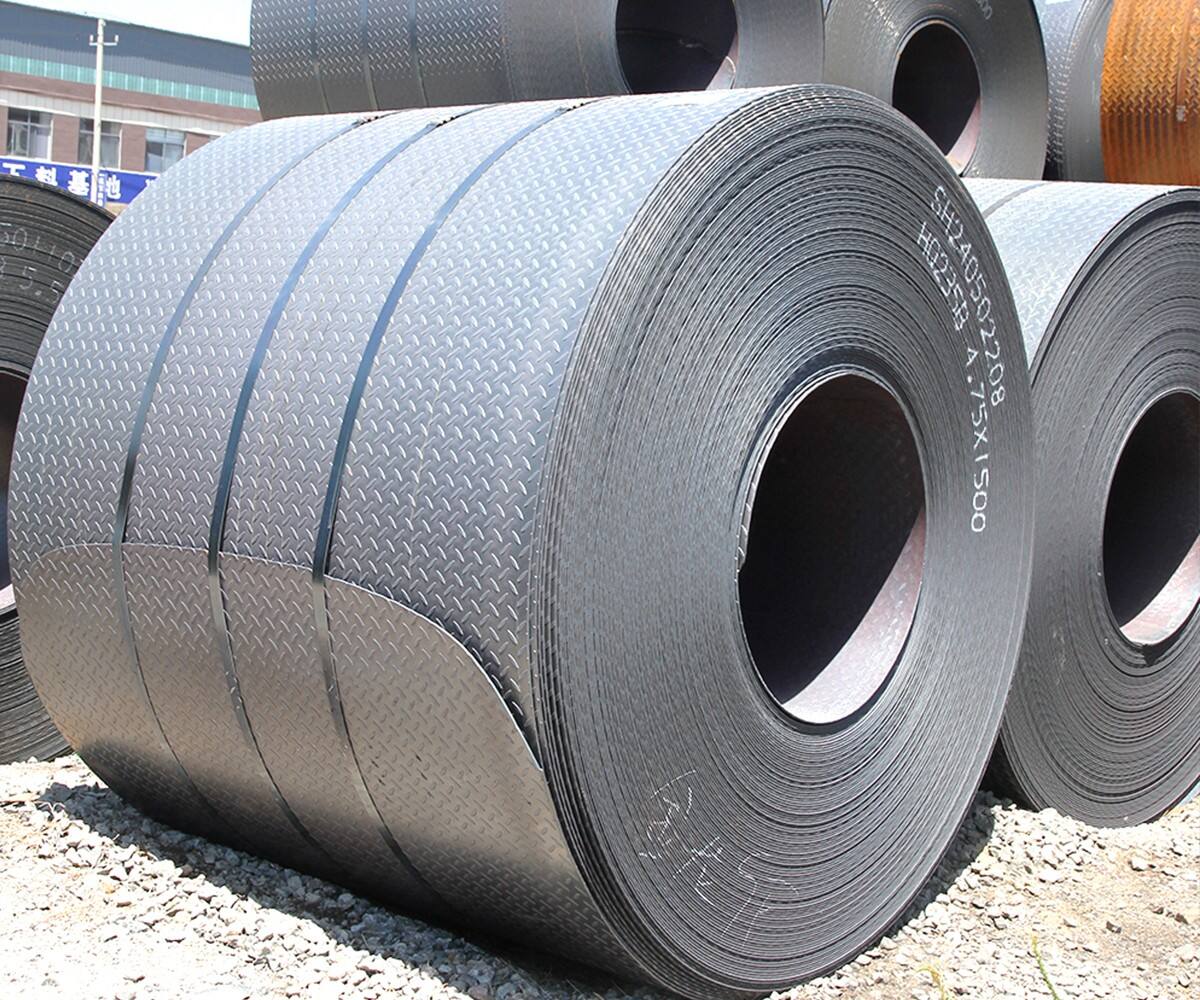

Identifying the quality of carbon steel coils is vital for ensuring the success of subsequent manufacturing and construction projects, and Shandong Hongzheng Metal Products Co., Ltd. can provide useful methods for this purpose. Visual inspection is the first step in identifying quality carbon steel coils. Examine the surface of the coil carefully. A high-quality carbon steel coil should have a smooth and uniform surface without obvious scratches, dents, or rust spots. Rust can indicate exposure to moisture and potential degradation of the material's properties. Any surface irregularities may affect the performance and usability of the coil in further processing. Additionally, check for consistent color and texture across the coil. Variations in color may suggest differences in the chemical composition or heat treatment process. Next, measure the dimensions of the carbon steel coil. The thickness, width, and outer diameter of the coil should conform to the specified standards and requirements. Use precise measuring tools, such as micrometers for thickness measurement and calipers for width and diameter measurement. Deviations from the specified dimensions can lead to problems during processing, such as improper fit in machinery or incorrect product dimensions. Chemical composition analysis is a more in-depth method to determine the quality of carbon steel coils. This can be done through laboratory testing. The main elements to analyze are carbon, manganese, silicon, sulfur, and phosphorus. The carbon content has a significant impact on the mechanical properties of the steel. A proper balance of other elements is also crucial for achieving the desired strength, ductility, and weldability. Shandong Hongzheng Metal Products Co., Ltd. provides detailed material certificates for its carbon steel coils, which include information on the chemical composition. Mechanical property testing is another important aspect. Tensile testing can be conducted to measure the strength and elongation of the carbon steel coil. A high-quality coil should have the specified tensile strength and good elongation, indicating its ability to withstand stress without breaking and its formability. Hardness testing can also be carried out to determine the hardness of the steel, which is related to its wear resistance and other properties. In addition, check for any signs of internal defects. Non-destructive testing methods, such as ultrasonic testing, can be used to detect internal flaws, cracks, or inclusions within the coil. These internal defects can significantly reduce the strength and reliability of the carbon steel coil. Shandong Hongzheng Metal Products Co., Ltd. adheres to strict quality control measures to ensure the high quality of its carbon steel coils. If you need more information on identifying quality carbon steel coils or have any questions about our products, please feel free to contact us. Our professional team will be happy to assist you.