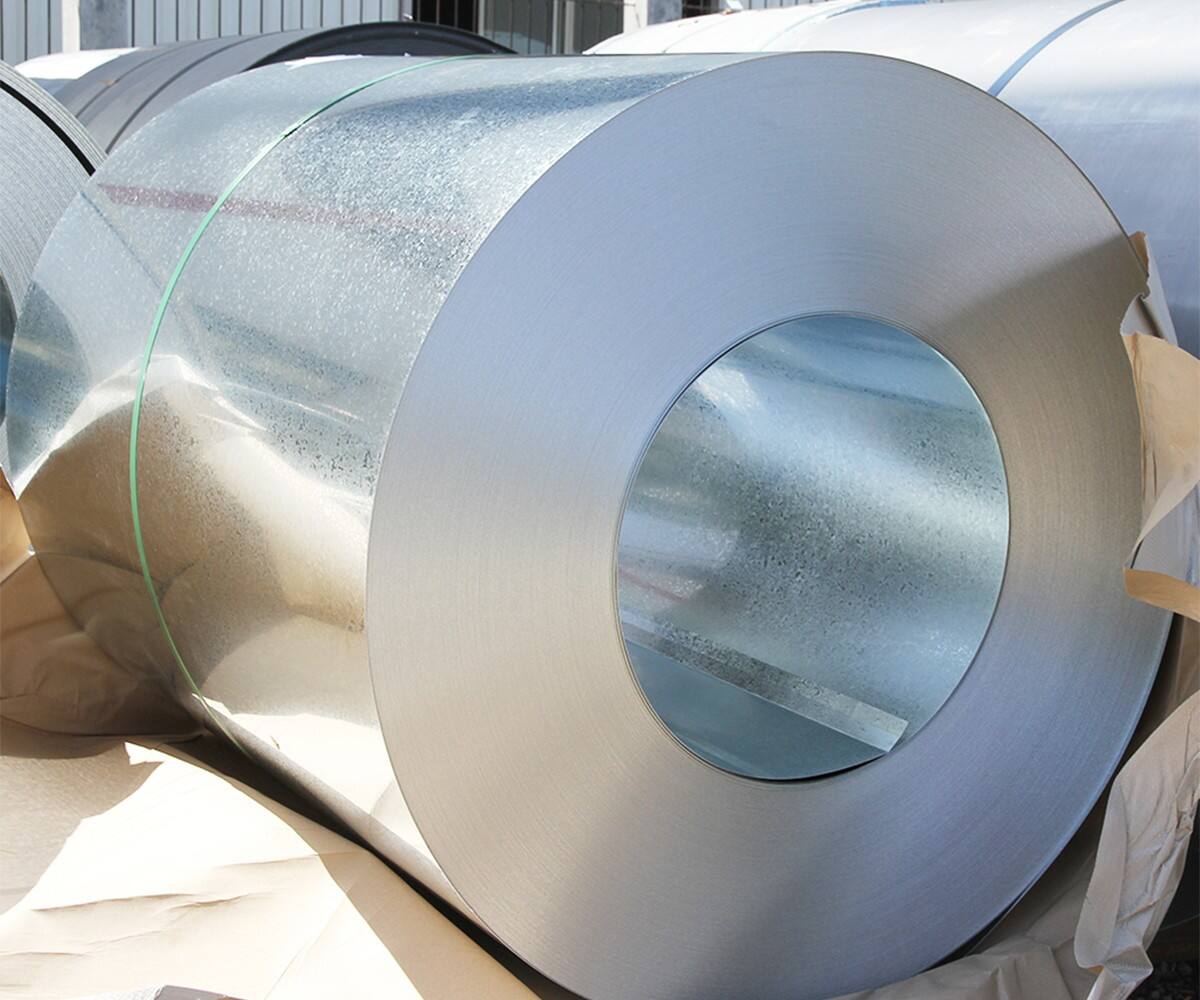

Pemeriksaan kekufungan keluli galvanis adalah langkah penting untuk memastikan kualitinya, prestasi, dan kesesuaiannya untuk aplikasi yang dimaksud. Proses pemeriksaan menyeluruh melibatkan pemeriksaan pelbagai aspek keluli, termasuk kualiti permukaan, ketebalan lapisan, sifat mekanikal, dan keakuratan dimensi. Langkah pertama dalam memeriksa keluli galvanis adalah pemeriksaan visual pada permukaan. Permukaan mestilah licin, seragam, dan bebas daripada kecacatan seperti garisan, cekungan, bintik karat, atau terkelupasnya lapisan galvanis. Sebarang kecacatan yang nampak mungkin menunjukkan masalah dengan proses pengeluaran atau isu potensial dengan integriti lapisan. Seterusnya, ketebalan lapisan galvanis diukur untuk memastikan ia memenuhi spesifikasi yang diperlukan. Ini boleh dilakukan menggunakan kaedah ujian tanpa merosak, seperti induksi magnetik atau ujian arus eddy. Ketebalan lapisan adalah perkara penting untuk menentukan ketahanan terhadap kerosakan keluli, dan ia mestilah seragam di seluruh permukaan. Sifat mekanikal, seperti kekuatan tarik dan kekuatan leleh, juga boleh dites untuk memastikan keluli memenuhi piawai yang diperlukan. Ini melibatkan pengambilan sampel dari keluli dan melakukan ujian tarik di makmal. Keakuratan dimensi adalah satu lagi aspek penting pemeriksaan. Lebar, ketebalan, dan panjang keluli mestilah diukur untuk memastikan ia mengikut dimensi yang ditetapkan. Sebarang sisihan dari dimensi yang diperlukan mungkin mempengaruhi kegunaan keluli dalam sesetengah aplikasi. Di Shandong Hongzheng Metal Products Co., Ltd., kami mempunyai proses kawalan kualiti yang ketat untuk memeriksa keluli galvanis kami secara menyeluruh. Pasukan kawalan kualiti berpengalaman kami menggunakan peralatan ujian moden dan kaedah untuk memastikan setiap gulungan memenuhi piawai tinggi kami. Jika anda memerlukan maklumat lanjut tentang bagaimana memeriksa keluli galvanis atau ingin membincangkan keperluan pemeriksaan tertentu untuk projek anda, sila hubungi kami.