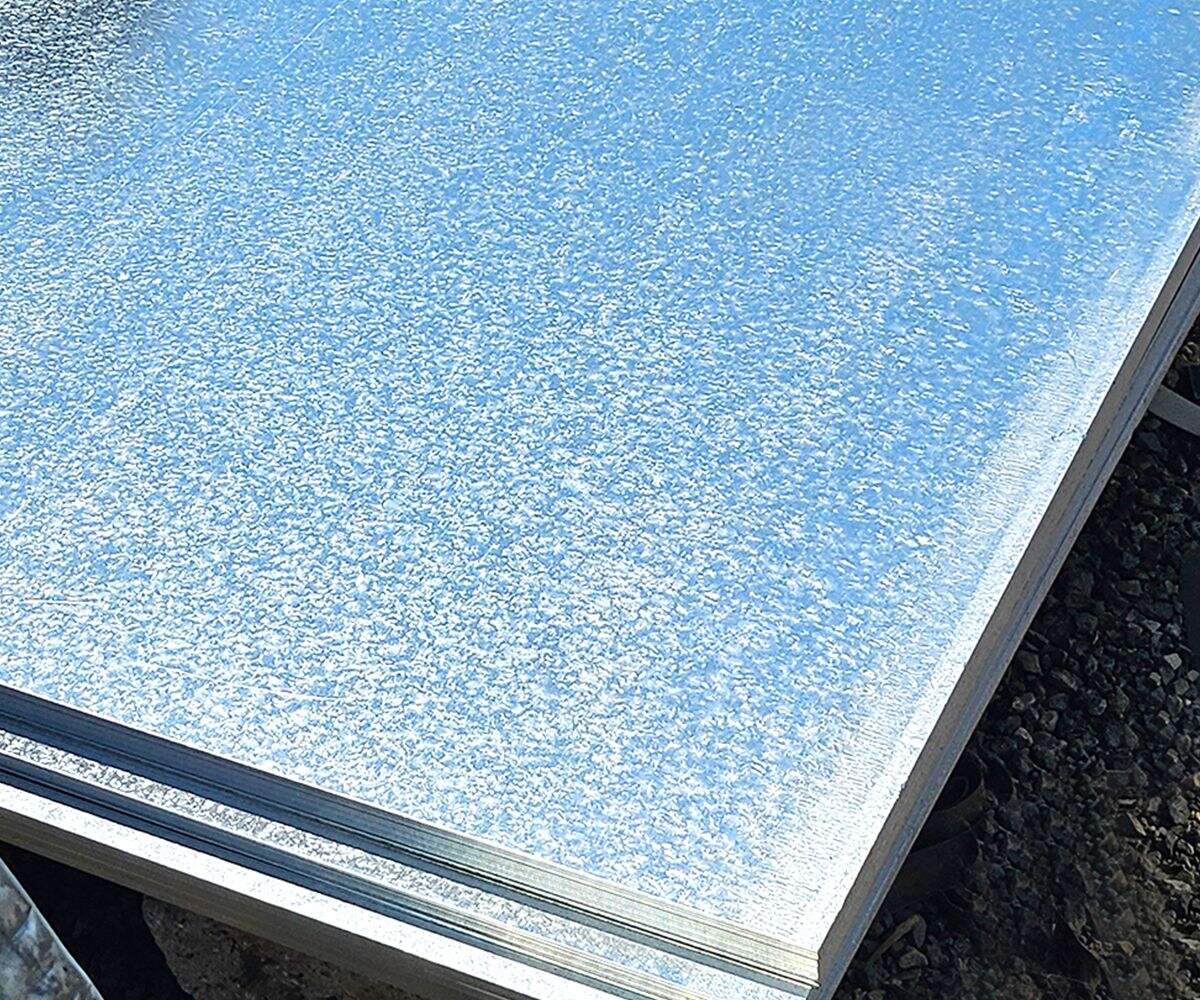

산둥 홍정 메탈 제품 유한공사의 아연도금 강판 코팅 공정은 전통적인 용융아연도금법과 현대 기술을 결합하여 우수한 내식성을 보장합니다. 이 공정은 먼저 표면 처리 단계에서 강판을 탈지, 산세 및 세척하여 불순물을 제거합니다. 다음으로 약 450°C의 용융 아연 욕조에 담가 강철과 아연 사이에 금속학적 결합을 형성합니다. 이를 통해 철-아연 합금층과 순아연 상층부로 구성된 코팅층이 생성되며, 두께는 55~275g/㎡ 범위입니다. 용융아연도금 공법은 복잡한 형상에서도 균일한 코팅이 가능하여 오랜 시간 동안 녹에 대한 보호를 제공합니다. 특정 요구사항에 따라 회사는 얇은 코팅을 위한 전기아연도금 또는 패시베이션 또는 도장과 같은 후코팅 처리도 제공합니다. 모든 공정 단계는 품질 관리를 위해 모니터링되어 코팅 부착력, 두께, 표면 마감이 국제 규격(ASTM A653, ISO 1461)을 준수하는지 확인합니다. 코팅 공정이나 맞춤형 솔루션에 대한 자세한 정보는 저희에게 문의해 주십시오.