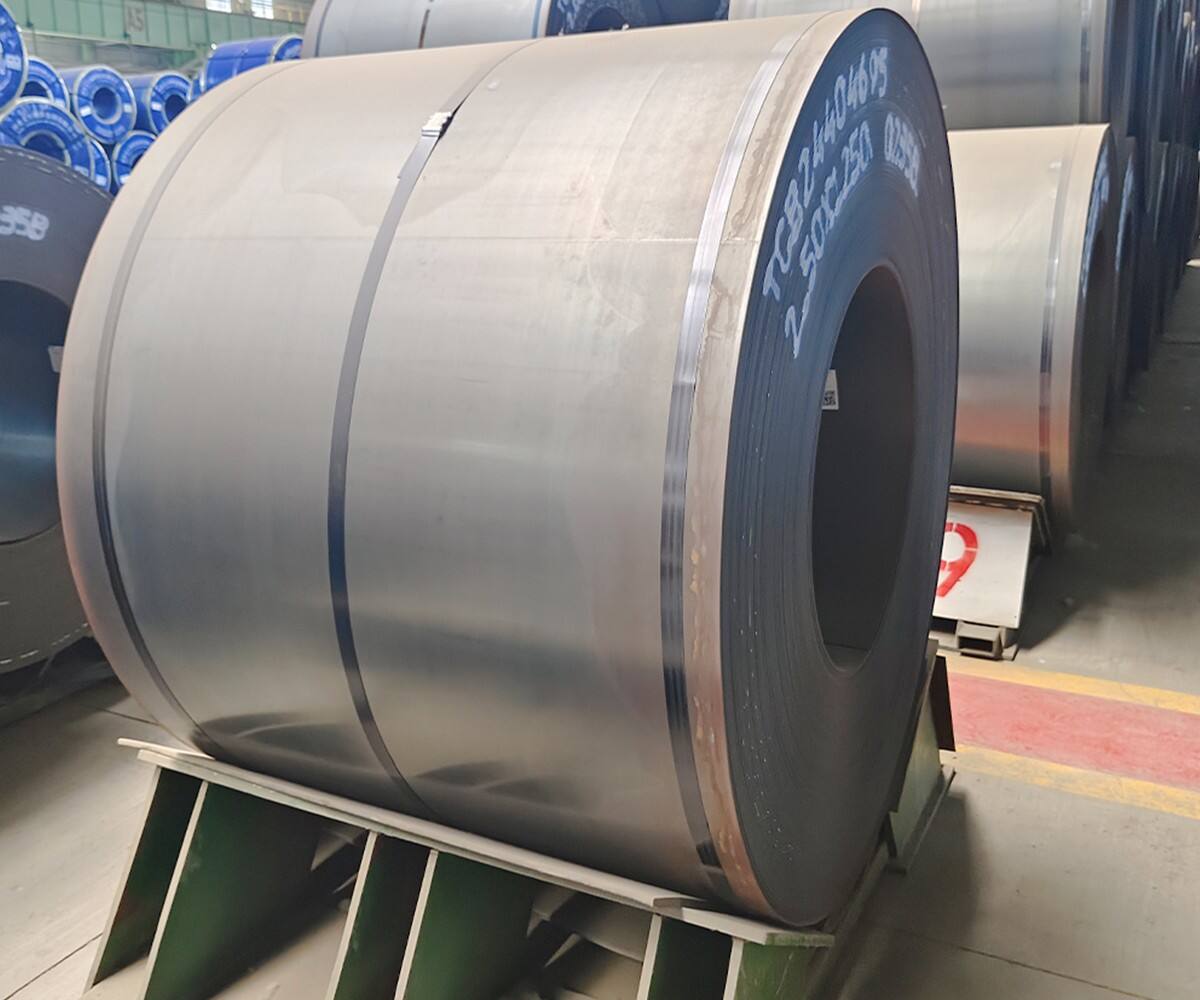

Le bobine d'acciaio al carbonio possiedono una gamma di proprietà che le rendono ampiamente utilizzate in varie industrie, e la Shandong Hongzheng Metal Products Co., Ltd. fornisce bobine d'acciaio al carbonio di alta qualità con caratteristiche eccellenti. Le proprietà meccaniche sono tra gli aspetti più importanti delle bobine d'acciaio al carbonio. La resistenza a trazione è una proprietà chiave, che si riferisce allo stress massimo che l'acciaio può sopportare prima di rompersi. Le bobine d'acciaio al carbonio con un contenuto di carbonio più elevato generalmente hanno una maggiore resistenza a trazione, ma potrebbero avere una minor duttilità. La duttilità consente all'acciaio di essere deformato senza rompersi, il che lo rende adatto a processi come il laminato, il piegamento e il stampaggio. La resistenza a snodo delle bobine d'acciaio al carbonio determina lo stress a partire dal quale il materiale inizia a deformarsi plasticamente. Un equilibrio appropriato tra resistenza a trazione e resistenza a snodo è cruciale per diverse applicazioni. La durezza è un'altra importante proprietà delle bobine d'acciaio al carbonio. È correlata alla resistenza del materiale all'usura, agli sfregi e alle indentazioni. Le bobine d'acciaio al carbonio ad alto contenuto di carbonio generalmente hanno una maggiore durezza e vengono spesso utilizzate in applicazioni dove è richiesta resistenza all'usura, come nella produzione di attrezzi e componenti macchina. Tuttavia, una maggiore durezza può anche rendere il materiale più difficile da lavorare e formare. La composizione chimica delle bobine d'acciaio al carbonio influenza significativamente le loro proprietà. Il carbonio è l'elemento principale di lega e il suo contenuto influisce sulla resistenza, durezza e duttilità dell'acciaio. Manganese, silicio, zolfo e fosforo sono presenti in quantità variabili. Il manganese può migliorare la resistenza e l'induribilità dell'acciaio, mentre il silicio ne migliora la resistenza e la resistenza all'ossidazione. Zolfo e fosforo, se presenti in quantità eccessive, possono avere effetti negativi sulle proprietà dell'acciaio, come ridurre la sua duttilità e tenacità. Le bobine d'acciaio al carbonio hanno anche alcune proprietà fisiche. Hanno una buona conducibilità termica, il che le rende adatte per applicazioni coinvolgenti il trasferimento di calore. La loro densità è relativamente alta, fornendo resistenza e stabilità in applicazioni strutturali. Inoltre, la conducibilità elettrica delle bobine d'acciaio al carbonio è relativamente bassa rispetto ad altri metalli, il che può essere un vantaggio in alcune applicazioni di isolamento elettrico. La resistenza alla corrosione è un aspetto che può essere migliorato attraverso vari trattamenti superficiali. Le bobine d'acciaio al carbonio sono soggette a arrugginire quando esposte all'umidità e all'ossigeno. Tuttavia, trattamenti come la galvanizzazione (rivestimento con zinco), la verniciatura o l'applicazione di rivestimenti antiruggine possono migliorare significativamente la loro resistenza alla corrosione, estendendo la loro durata in diversi ambienti. La Shandong Hongzheng Metal Products Co., Ltd. controlla attentamente il processo produttivo per garantire che le bobine d'acciaio al carbonio fornite abbiano proprietà coerenti ed eccellenti. Se desideri sapere di più sulle proprietà delle bobine d'acciaio al carbonio o hai requisiti specifici per i prodotti, contattaci. Siamo dedicati a fornirti informazioni dettagliate e bobine d'acciaio al carbonio di alta qualità per soddisfare le tue esigenze.