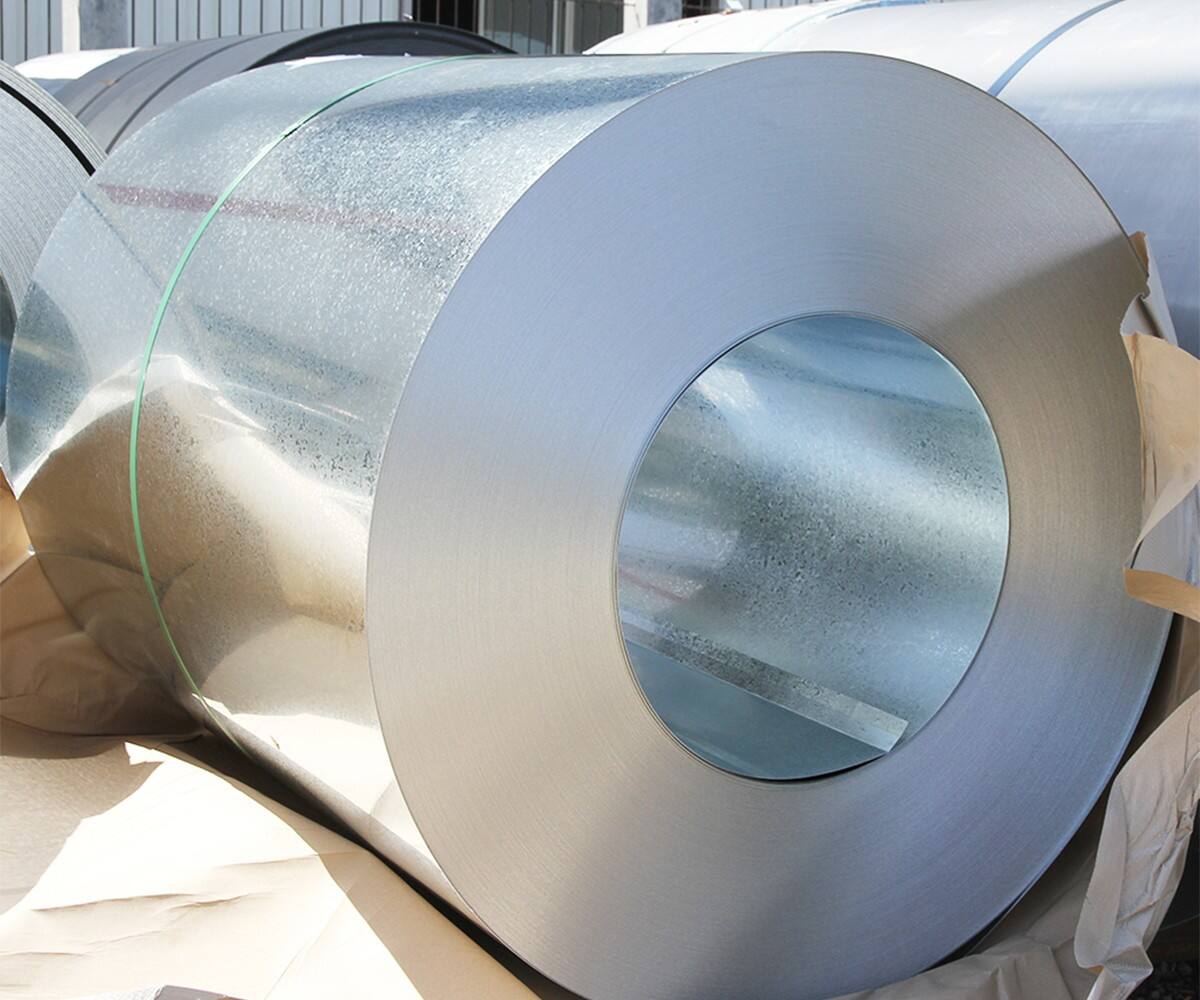

Η επιλογή της σωστής μαλαμάτινης χάλκινης κούνεας απαιτεί να λάβετε υπόψη πολλά κλειδιά παράγοντες για να εξασφαλιστεί η καλύτερη δυνατή απόδοση και οικονομική αποτελεσματικότητα. Η Shandong Hongzheng Metal Products Co., Ltd., με την ειδικευμένη γνώση της σε προϊόντα από χάλκα, προσφέρει επαγγελματικές κατευθύνσεις για αυτήν την διαδικασία. Πρώτα, καθορίστε την προορισμένη χρήση, καθώς διαφορετικές χρήσεις—όπως κατασκευή, αυτοκινητοβιομηχανία ή κατασκευή ελαφρών ηλεκτρονικών συσκευών—έχουν συγκεκριμένες απαιτήσεις. Για την κατασκευή, προτεραιοτήτα δίνεται σε κούνεες με υψηλότερα βάρη καλύψεως μαλάματος (π.χ., 275 g/m²) για βελτιωμένη αντοχή στη διάβρωση, ενώ οι εφαρμογές στην αυτοκινητοβιομηχανία μπορεί να απαιτούν καλύτερη μορφοποίηση. Στη συνέχεια, αξιολογήστε την κλάση χάλκας και τις μηχανικές ιδιότητες, όπως η σφυγμική ισχύς και η ισχύς παράδοσης, για να ταιριάζουν με τις δομικές ανάγκες. Η πάχος και το πλάτος της κούνεας πρέπει να συμφωνούν με τις προδιαγραφές του έργου, με κοινές πάχεις που μεταξύ 0,15 mm έως 4,0 mm. Η επιφανειακή ολοκλήρωση είναι άλλη μια παράμετρος· επιλογές περιλαμβάνουν με αστράκια, αχρωμές ή προ-ζωγραφισμένες επιφάνειες, ανάλογα με τις αισθητικές και λειτουργικές ανάγκες. Επιπλέον, ελέγξτε την κολλητικότητα και την ομοιομορφία της κάλυψης, καθώς κακή κάλυψη μπορεί να οδηγήσει σε πρόωρη διάβρωση. Οι μαλαμάτινες χάλκινες κούνεες της εταιρείας υποβάλλονται σε αυστηρές δοκιμασίες για το πάχος κάλυψης, τις μηχανικές ιδιότητες και την ποιότητα της επιφάνειας, εξασφαλίζοντας τη συμμόρφωση με διεθνείς πρότυπα όπως το ASTM A653 και το ISO 1461. Για προσωπικές συμβουλές για την επιλογή της σωστής μαλαμάτινης χάλκινης κούνεας για το έργο σας, επικοινωνήστε με την ομάδα πωλήσεων μας.