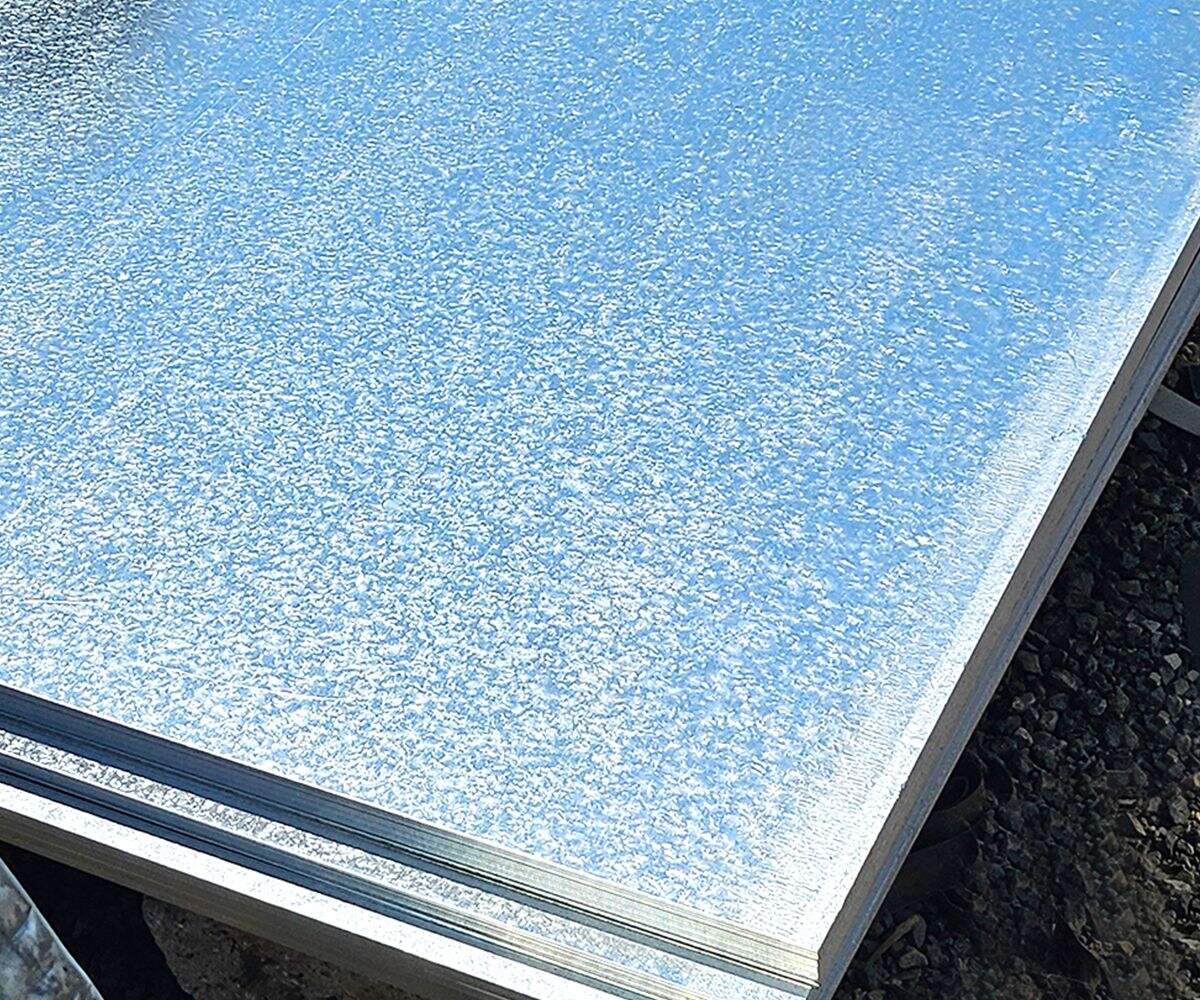

The galvanized steel plate coating process at Shandong Hongzheng Metal Products Co., Ltd. combines traditional hot-dip galvanization with modern technology to ensure superior corrosion resistance. The process begins with surface preparation: plates are degreased, pickled, and rinsed to remove impurities. Next, they are dipped into a molten zinc bath at approximately 450°C, forming a metallurgical bond between the steel and zinc. This creates a coating composed of zinc-iron alloy layers and a pure zinc top layer, with thicknesses ranging from 55 to 275 g/m². The hot-dip process ensures uniform coating even in complex geometries, providing long-lasting protection against rust. For specific needs, the company also offers electro-galvanizing for thinner coatings or post-coating treatments like passivation or painting. Each step is monitored for quality, ensuring coating adhesion, thickness, and surface finish meet international standards (ASTM A653, ISO 1461). For detailed information on coating processes or custom solutions, please contact us.