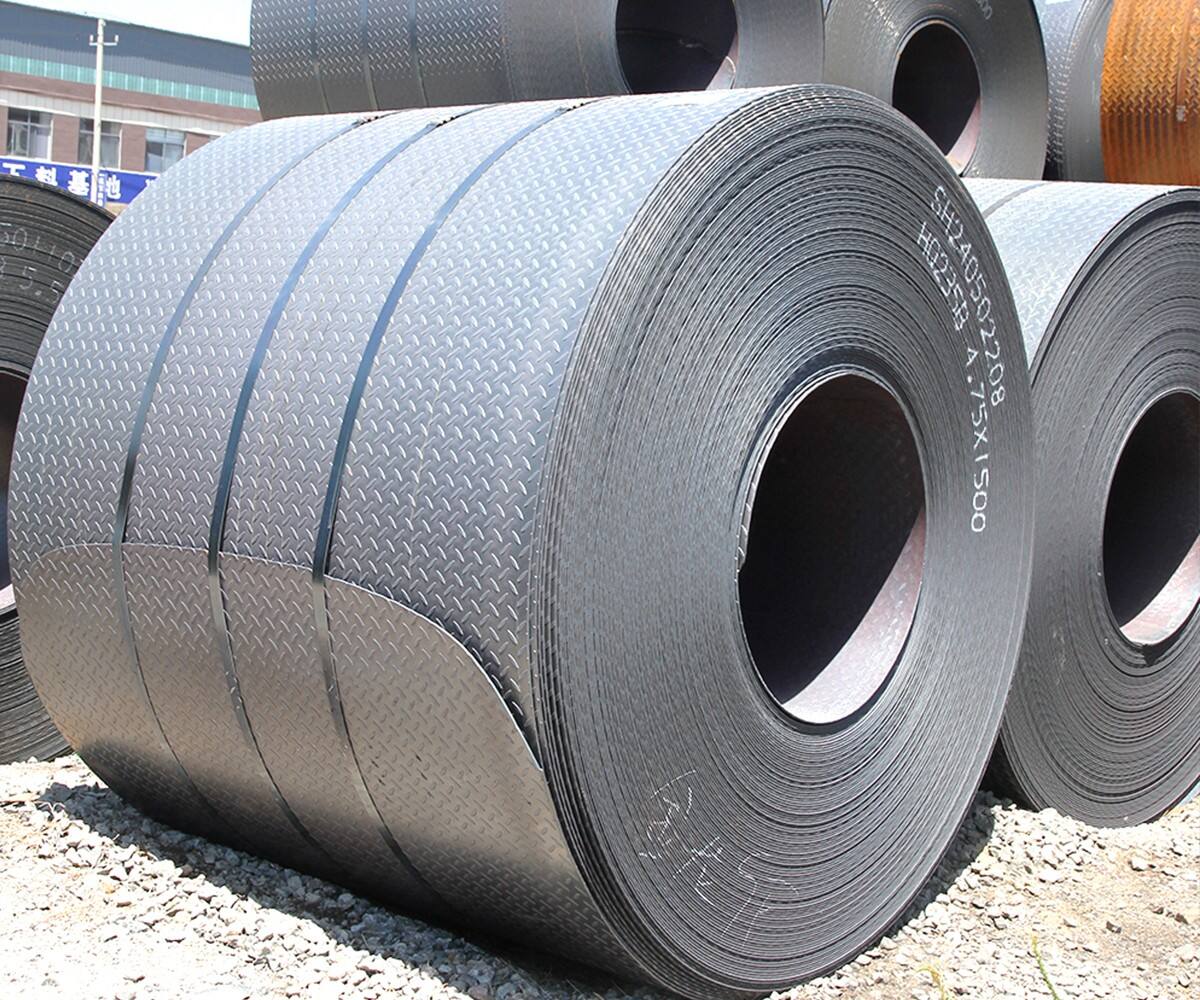

탄소강 코일의 품질을 식별하는 것은 후속 제조 및 건설 프로젝트의 성공을 보장하기 위해 중요하며, 산동 홍정 메탈 프로덕츠 주식회사는 이 목적을 위해 유용한 방법들을 제공할 수 있습니다. 시각 검사는 탄소강 코일의 품질을 식별하는 첫 번째 단계입니다. 코일의 표면을 신중하게 검사하세요. 고품질의 탄소강 코일은 명확한 긁힘, 움푹 들어간 부분 또는 녹 얼룩이 없는 매끄럽고 균일한 표면을 가져야 합니다. 녹은 물에 노출되었음을 나타낼 수 있으며, 이는 재료의 특성이 저하될 가능성을 암시합니다. 표면의 불규칙성은 추가 가공에서 코일의 성능과 사용성을 영향을 미칠 수 있습니다. 또한 코일 전체의 일관된 색상과 질감을 확인하세요. 색상의 차이는 화학적 조성이나 열처리 공정의 차이를 나타낼 수 있습니다. 다음으로, 탄소강 코일의 치수를 측정합니다. 코일의 두께, 너비 및 외경은 지정된 표준 및 요구 사항에 부합해야 합니다. 두께 측정에는 마이크로미터를, 너비와 직경 측정에는 캘리퍼스를 사용하는 등 정밀한 측정 도구를 사용하세요. 지정된 치수에서 벗어나면 기계에서의 부적절한 맞춤이나 제품 치수의 오류와 같은 가공 중 문제가 발생할 수 있습니다. 화학적 조성 분석은 탄소강 코일의 품질을 결정하기 위한 더 깊이 있는 방법입니다. 이를 실험실 테스트를 통해 수행할 수 있습니다. 주요 분석 요소는 탄소, 망간, 규소, 황 및 인입니다. 탄소 함량은 강의 역학적 특성에 큰 영향을 미칩니다. 다른 요소들의 적절한 균형도 필요한 강도, 연성 및 용접성 달성에 있어 매우 중요합니다. 산동 홍정 메탈 프로덕츠 주식회사는 탄소강 코일의 화학적 조성을 포함한 자세한 재료 증명서를 제공합니다. 역학적 특성 테스트는 또 다른 중요한 요소입니다. 인장 시험을 통해 탄소강 코일의 강도와 신장을 측정할 수 있습니다. 고품질 코일은 지정된 인장 강도와 좋은 신장 능력을 가지고 있어야 하며, 이는 스트레스를 견디고 형태를 유지할 수 있는 능력을 나타냅니다. 경도 시험도 강의 경도를 결정하기 위해 수행될 수 있습니다. 이는 마모 저항 및 기타 특성과 관련이 있습니다. 또한 내부 결함의 징후를 확인하세요. 초음파 검사와 같은 비파괴적 검사 방법은 코일 내부의 결함, 균열 또는 섞임물을 감지하는 데 사용할 수 있습니다. 이러한 내부 결함은 탄소강 코일의 강도와 신뢰성을 크게 줄일 수 있습니다. 산동 홍정 메탈 프로덕츠 주식회사는 탄소강 코일의 고급 품질을 보장하기 위해 엄격한 품질 관리 조치를 준수하고 있습니다. 탄소강 코일의 품질 식별에 대한 추가 정보가 필요하거나 우리 제품에 대해 질문이 있으면 언제든지 문의해 주세요. 전문적인 팀이 기꺼이 도와드리겠습니다.