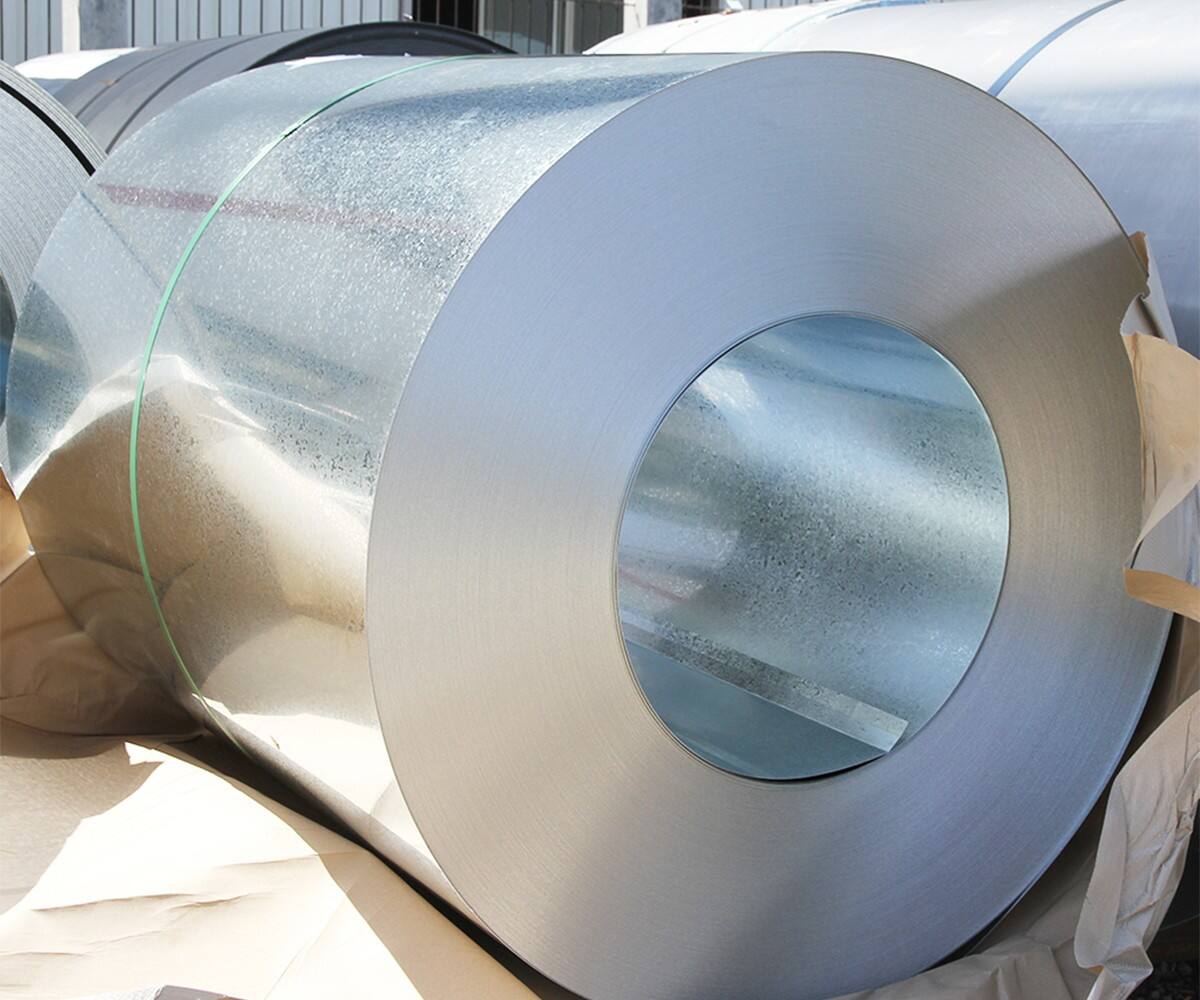

A galvanizált acélkötés vizsgálata fontos lépés annak biztosítására, hogy megfeleljen a minőségi, teljesítményi követelményeknek és alkalmas legyen az előre meghatározott alkalmazásra. A részletes ellenőrzési folyamat során különböző aspektusokat kell ellenőrizni a kötésen, beleértve a felületi minőségét, a fedőszint vastagságát, mechanikai tulajdonságait és méretei szerinti pontoságot. A galvanizált acélkötés vizsgálatának első lépése a felület szemészeti vizsgálata. A felület sima, egyenletes és hibák, mint például a röcsök, gödörök, rések vagy a galvanizált fedőanyag leborítása nélkül kell, hogy legyen. Bármi látható hiba jelezhet gyártási problémát vagy potenciális gondot a fedőszín integritásával kapcsolatban. Ezután a galvanizált fedőszín vastagságát mérjük, hogy megfeleljen a szükséges specifikációknak. Ezt nem zártó tesztelési módszerekkel lehet elvégezni, például magnes indukcióval vagy eddy áram teszteléssel. A fedőszín vastagsága döntő szerepet játszik az acélkötés rovarmentesítési ellenállásának meghatározásában, és egyenletesnek kell lennie az egész felületén. A mechanikai tulajdonságok, például a húzás erőssége és a nyomás erőssége is tesztelésre kerülhet, hogy megfeleljenek az acélkötésnek a szükséges szabványoknak. Ez azt jelenti, hogy a kötésből mintákat veszünk és húzás teszteket végezünk laboratóriumi körülmények között. A méretei szerinti pontoság egy másik fontos elem a vizsgálat során. A kötés szélességét, vastagságát és hosszát mérjük, hogy megfeleljenek a megadott méreteknek. Bármilyen eltérés a szükséges méretekektől befolyásolhatja a kötés használhatóságát bizonyos alkalmazásokban. A Shandong Hongzheng Metal Products Co., Ltd.-nél szigorú minőségbiztosítási folyamat van érvényben a galvanizált acélkötéseink teljes körű ellenőrzésére. Tapasztalt minőségbiztosítási csapataink haladó tesztelési eszközöket és módszereket használnak annak biztosítására, hogy minden kötés megfeleljen magas szabványainknak. Ha több információt szeretne arról, hogyan kell vizsgálni a galvanizált acélkötést, vagy beszélni szeretne egy adott projektjehez tartozó konkrét ellenőrzési követelményekről, kérjük, vegye fel velünk a kapcsolatot.